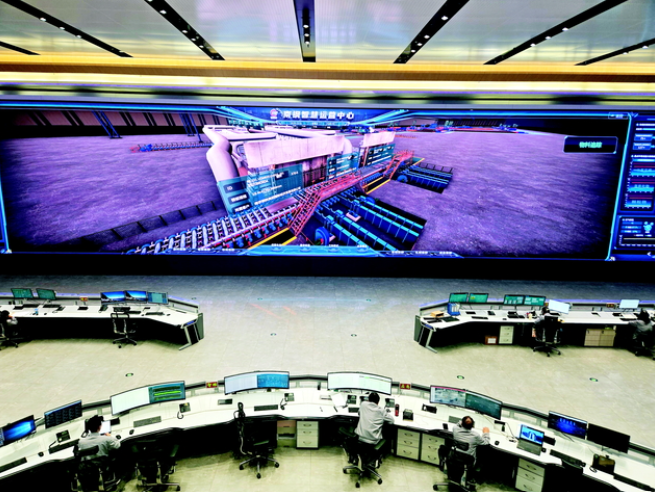

When entering the smart operations center of Nanjing Iron & Steel Group (Nangang) in Nanjing, Jiangsu Province on the 21st of last month, visitors were immediately struck by an enormous display measuring 42 meters long and 6 meters high. On this screen, the company’s massive steelmaking facilities and production lines appeared as a fully realized 3D virtual model — a so-called digital twin. Fewer than ten employees sat before the display, monitoring real-time production conditions from their seats.

The screen presented a complete live visualization of the steel mill. As the view shifted from the overall facility to individual buildings, the real-time status of major equipment—cranes, converters, continuous casters, and more—appeared instantly. Various data overlays were displayed as well. By selecting “Raw Materials Cluster,” staff could see how many ore-carrying vessels were docked at the port and how key raw materials like coal and coke were being transported through belt conveyor systems in real time. On the “Steelmaking Management” page, they could immediately check the refining cycle, processing time, and steel grade produced by each converter. Any anomaly triggered an instant system alert.

A Nangang representative explained: “We integrated 26 production lines, one million data points, and thousands of operational models into a one-to-one mapping between real and virtual processes. From raw material intake to final product shipment, all stages of production, supply, and logistics are fully digitized and unified.”

Nangang is deeply integrating advanced digital technologies—AI, 5G, and digital twins—into steel manufacturing, fundamentally transforming traditional production and service models while building a new digital ecosystem for the steel industry. To achieve this, the company signed a comprehensive cooperation agreement with Huawei and invested more than 4 billion yuan. Over the past five years, Nangang reports achieving a 10% reduction in quality-related costs per ton, a 20% reduction in R&D expenditures, a 5% increase in the forming rate of high-grade products, and a 3% cost reduction across the entire industrial supply chain.

AI has taken on an especially large role in quality inspection. More than 100 smart robots now handle quality checks on steel products before shipment. During a demonstration of automated metallographic analysis for visiting reporters, a robot accurately picked up a cut piece of steel plate, placed it under a microscope, and began inspection. “The robot automatically performs cutting, grinding, etching, and imaging,” a representative explained. “Algorithms then analyze the microstructure and assign quality grades. Inspection efficiency has increased by more than 50%.” With the introduction of AI, the number of skilled technical workers dropped from more than 30,000 to about 10,000.

Nangang’s smart factory project was recently named a “leading-level” smart factory by the Ministry of Industry and Information Technology—the highest of the four-tier classification system, which ranges from Basic to Advanced, Excellent, and Leading. At a meeting in March with Huawei Executive Director Wang Tao, Nangang Chairman Huang Yixin stated, “The steel factory of the future will be dominated by AI. Nangang will present a new paradigm for the steel industry through AI integration.”

At a petrochemical plant filled with heat and chemical fumes, robots—not humans—patrol the corridors. This is the main role of the explosion-proof quadruped robots produced by China’s Qitong Robotics.

During a visit to the company’s headquarters on the 28th of last month, Qitong was introduced as one of China’s top three players in the specialty robotics sector. Its self-developed explosion-proof quadruped robot is its flagship product, currently used in more than 3,500 companies across over 40 countries and regions. The key advantage is its explosion-proof design, which enables deployment in high-risk sites such as petrochemical facilities. Zhang Zhe, head of planning at Qitong, said, “Across our 3,500 clients, we’ve monitored around 50,000 safety alerts and detected roughly 500 potential accidents in advance.” He explained that quadrupeds—unlike wheeled robots—are preferred because they can traverse uneven roads, gravel paths, and even climb stairs.

Powered by AI, the robot moves autonomously, inspects facilities, and makes instant decisions when issues arise. “The robot doesn’t just collect specific information or data,” Zhang said. “It can perform various tasks using built-in options. It detects issues through its own sensors, interprets the data, judges the situation, and then takes direct action. For example, if it detects a fire hazard, it uses its onboard extinguisher to spray water and put out the flames. With deep learning, these robots continually visit thousands of sites, improving their performance over time.”

Zhang added, “A human safety inspector earns about 10,000 yuan per month. One robot can cover the workload of six to eight people. Since a single robot can operate for around 10 years, clients save at least 8 million yuan over that period while significantly improving safety.”

On the 28th of last month, at the Western Autonomous Driving Test and Demonstration Zone in Yongchuan District, Chongqing, visitors experienced Baidu’s sixth-generation autonomous vehicle, the RT6. A key feature of the RT6 is advanced voice control, enabling passengers to open windows, adjust lighting, and issue other commands. Every order given during the test drive was executed smoothly without errors. When asked to “drive faster,” the car replied, “I cannot exceed the safety-regulated speed.” The driving behavior is said to be more human-like than the fifth-generation model, with more natural responses to unexpected situations.

The RT6 is considered a major milestone toward scalable robotaxi deployment, as it was built as a dedicated autonomous vehicle from the ground up—not converted from an existing car—and was designed at a relatively low cost to support mass adoption. Baidu also noted that the steering wheel is removable, allowing flexible use of the interior space.

Yongchuan currently operates a 1,576-square-kilometer autonomous driving demonstration zone, where around 60 Level-4 autonomous vehicles—capable of fully automated driving without human intervention—are in operation. Total recorded safe driving distance has surpassed 9.81 million kilometers and is expected to soon exceed 10 million. Yongchuan is also the first place in the world to begin pilot operation of the RT6. Baidu representatives said Chongqing’s mountainous terrain offers valuable conditions for machine learning: “The complex environment allows vehicles to learn from a wider range of scenarios, contributing to safer autonomous driving.”

JENNIFER KIM

US ASIA JOURNAL